Test pumps

- Pneumatic and hydraulic pressure pumps

- Pressure ranges -0.95...1400 bar

- Ideal for mobile use

- Power supply not necessary

- Assembly, commissioning

- Manufacturing, production

- Maintenance, service

- Quality assurance, test equipment monitoring

- repair

Pressure is a frequently measured quantity in technology, which is why interest in accurate and reliable pressure measurement is particularly high. However, even the best sensors or transducers change their characteristic properties due to various influences. This leads to drift and incorrect display values. These deviations can be detected by regular checks and documented with a certificate. Before commissioning, all pressure measuring devices that have a significant influence should be calibrated. SIKA's mobile test and calibration devices are effective helpers to quickly perform these testing tasks.

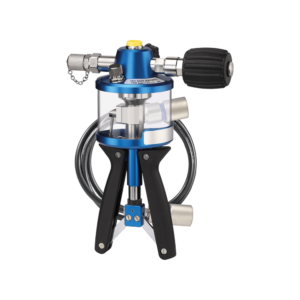

Pneumatic hand test pumps are operated with air as the pressure medium and are particularly suitable for applications where the test specimen must not be wetted or aggressive or ionizing substances must be avoided. SIKA's pneumatic test pump meets requirements that other suppliers can often only cover with several pumps. SIKA test pumps and pressure generators can be used to test, adjust and calibrate pressure sensors, pressure gauges, pressure switches, safety valves and various pressure devices. They are optimized in function and handling and support you in performing your test and inspection tasks.

Hydraulic hand test pumps use water or oil as the pressure medium and have been specially developed for the medium to high pressure range. They are easy to operate and have a built-in reservoir as a container for the hydraulic fluid. Depending on the model, pressures of up to 350 bar, 700 bar or 1000 bar can be generated. SIKA test pumps and pressure generators can be used to test, adjust and calibrate pressure sensors, pressure gauges, pressure switches, safety valves and various pressure devices. They are optimized in function and handling and help you to fulfill your testing and inspection tasks.

The latest generation of hydraulic benchtop test pumps from SIKA combines precision at high pressures with high processing quality. Depending on the model, distilled water and/or hydraulic oil can be used as test medium. The sophisticated design of these comparison test pumps allows effortless mounting of test specimens, even with large nominal diameters. The built-in adapters on the pressure connections also allow free alignment of the reference manometer and the test item. The filling of the pressure body and the generation of the test pressure are easily done via a rotatable spindle. The pressure medium reservoir installed as standard on the test pump enables large volumes to be charged without difficulty. Pressure fluctuations due to air and gas components, compensation of thermodynamic effects as well as an exact adjustment of the desired test pressure are carried out via the fine adjustment (optional). All wetted parts are made of stainless steel to ensure wear-free operation.

SIKA's lightweight high-pressure hydraulic benchtop pumps have a compact design and yet feature a large nylon tank with a usable tank volume of 327 cm³. With a delivery volume of 0.9 cm³ per piston stroke, they offer the possibility of testing several test specimens in parallel. They are mounted directly on the supplied pressure hose or via a separate distribution block, which saves time and makes your testing task extremely efficient. The integrated check valve in the pressure body allows stable pressure conditions to be generated very quickly. The built-in safety valve protects against overloads.

-

Type P4 Manual test pumps Pressure range -0.3...4 bar

-

Type P40.2 Manual test pumps Pressure range up to 40 bar

-

Type P60 manual test pumps Pressure range up to 60 bar

-

Type P700.T tabletop test pumps with lever Pressure range up to 700 bar

-

Type P700.3 Manual test pumps Pressure range up to 700 bar

-

Type P1000.2 Manual test pumps Pressure range up to 1000 bar

-

Type P700.G2 bench test pumps with spindle wheel Pressure range up to 700 bar

-

Type P700.GW / bench test pumps with spindle wheel / pressure range up to 700 bar

-

Type P1400.G bench test pumps with spindle wheel Pressure range up to 1400 bar